Bez kategorii

Sandwich panels: application, assembly and fastening systems

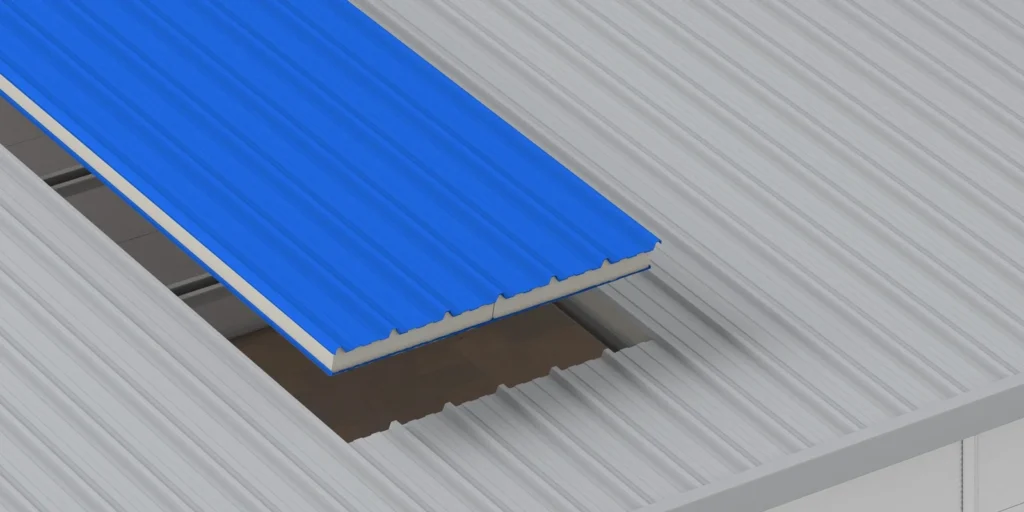

Sandwich panels are a modern and innovative building material that is becoming increasingly popular in various construction sectors. Their versatility and exceptional efficiency make them a popular choice for both architects and engineers. Thanks to their unique structure, consisting of several layers, these panels offer excellent insulation properties and impressive durability. This makes them an ideal solution for a wide range of construction projects.

Technological progress in construction opens up new possibilities for us, and sandwich panels play a key role in this. They allow the creation of structures that are energy-efficient, durable and aesthetic at the same time. Imagine how this material can affect the future of construction by changing our approach to modern construction solutions!

What are sandwich panels?

Sandwich panels are an innovative and versatile building material, consisting of two facings and an insulating core. Thanks to their well-thought-out design, they are used in many areas of construction – from industrial, through commercial, to residential. What makes them so popular? It is a combination of durability, excellent insulation and ease of installation. These features make them an ideal choice for a variety of construction projects.

Structure and properties of sandwich panels

The key feature of sandwich panels is their unique construction. The outer layers provide high mechanical strength, while the core is responsible for excellent thermal insulation. What’s more, the core can be made of various materials, such as:

- Mineral wool – characterized by high fire resistance.

- Polyurethane foam (PIR) – offering excellent thermal insulation.

- Styrofoam – an economical solution with good insulation.

Thanks to this diversity, sandwich panels can be easily adapted to the specific requirements of each project. Whether your priority is fire safety, energy efficiency or cost optimization, these materials will meet your expectations.

Application in industrial, commercial and residential construction

Sandwich panels are widely used in various construction sectors:

- Industrial construction – ideal for building warehouses, logistics centres or production facilities.

- Commercial sector – they are perfect for building shopping centers, pavilions or office buildings.

- Residential construction – increasingly used for the construction of single-family homes and modular buildings.

Why are sandwich panels so popular? They offer quick assembly, excellent insulation and aesthetic appearance. Their versatility and functionality make them a popular choice among both investors and developers.

Types of sandwich panels

In the dynamically developing world of construction, sandwich panels have gained enormous popularity. Their versatility and efficiency make them irreplaceable in many projects. Depending on the purpose, there are three main types of sandwich panels:

- Wall panels – used in external and internal wall cladding.

- Roof panels – intended for roof coverings, resistant to mechanical loads.

- Refrigeration plates – used in the construction of cold stores and freezers.

Each of these types has unique properties that make them an ideal choice for a variety of applications.

Wall sandwich panels

Wall sandwich panels are one of the most frequently chosen materials in construction. Their key features include:

- Excellent thermal and acoustic insulation – ensuring thermal comfort and noise reduction.

- Aesthetics and functionality – ideal for both residential and commercial buildings.

- Energy Efficiency – Modern office buildings often use these panels to reduce energy consumption.

An example of their use are modern office buildings, which, thanks to these panels, combine attractive appearance with energy efficiency.

Roof sandwich panels

Roof sandwich panels are designed specifically for roofing. Their key advantages include:

- Exceptional thermal insulation – helps maintain a stable temperature inside buildings.

- Resistance to mechanical loads – ideal for structures exposed to difficult weather conditions.

- Weather resistance – resistance to strong winds and heavy snowfall.

- Energy savings – reduce the costs of heating and cooling buildings.

Typical applications are warehouses, where ensuring appropriate thermal conditions is crucial.

Refrigeration sandwich panels

Refrigeration sandwich panels play a key role in the construction of cold stores and freezers. Their most important features are:

- Exceptional insulating properties – enable maintaining low temperatures.

- Precise control of conditions – ideal for storing temperature-sensitive products.

- Wide application – used in the food and pharmaceutical industries.

- Guarantee of quality and safety – especially in pharmaceutical warehouses where medicines are stored.

An example of their use is pharmaceutical warehouses, where cooling plates provide appropriate conditions for storing temperature-sensitive drugs.

Insulation materials in sandwich panels

Selecting the right insulating material for sandwich panels is a key factor that affects their thermal insulation properties and range of applications. These panels can be equipped with different types of cores, such as PIR foam, mineral wool or polystyrene. Each of these materials has unique features that determine their energy efficiency and functionality in construction. Choosing the right solution depends on the specifics of the project and its priorities.

PIR Foam Core: Advantages and Applications

PIR foam core is one of the most effective insulating materials used in sandwich panels. Its popularity is due to its excellent thermal insulation properties and high fire resistance. Rigid polyisocyanurate foam minimizes heat loss, making it an ideal choice for projects where energy efficiency is key.

- Thermal insulation: Effectively reduces heat loss, which translates into energy savings.

- Fire resistance: High fire resistance increases building safety.

- Application: Mainly in industrial and commercial buildings where maintaining the appropriate temperature is a priority.

PIR core panels are particularly recommended for use in facilities where energy savings and maintaining stable thermal conditions are key.

Mineral Wool Core: Fire Resistance and Acoustics

If fire safety and acoustic comfort are your priorities, a mineral wool core is an excellent choice. This material is not only non-flammable, but also has exceptional fire resistance, making it an ideal solution for buildings with increased safety requirements.

- Fire resistance: Mineral wool is non-flammable and provides high fire protection.

- Acoustic insulation: Excellent sound insulation, making it ideal for places requiring noise reduction.

- Application: Concert halls, recording studios, offices and other spaces where acoustics play an important role.

Mineral wool is a material that combines safety with comfort of use, which makes it irreplaceable in many demanding projects.

Styrofoam sandwich panels: An economical solution

Styrofoam sandwich panels are an option for those looking for an economical solution that combines an affordable price with good thermal insulation. Styrofoam is known for its ease of installation and low costs, making it a popular choice in industrial construction.

- Affordable price: Styrofoam is one of the most economical solutions on the market.

- Ease of assembly: Easy to process and install, which speeds up project implementation.

- Thermal insulation: Provides solid thermal insulation properties at an affordable price.

- Limitations: Lower fire resistance compared to other materials.

Styrofoam is an ideal choice for projects with a limited budget, where it is crucial to obtain good thermal insulation at minimal cost.

Sandwich panel fastening systems

Choosing the right sandwich panel mounting system is a key step in achieving harmony between the aesthetics and functionality of a building. These systems are divided into two main types: visible and hidden. Each of them affects both the appearance of the façade and the method of installation. Depending on the specifics of the project, investors can choose a solution that is ideally suited to their needs – both visually and technically.

Plates with visible fastening

Sandwich panels with visible fastening are particularly popular in industrial and commercial construction. Their main advantages are:

- Ease of assembly – an ideal solution for projects where time is of the essence.

- Solidity and durability – visible connectors ensure structural stability, which is important in facilities requiring high durability.

- Ease of maintenance – the design allows for quick repairs and replacement of components.

These prefabricated elements are used in the construction of:

- warehouse halls,

- logistics centers,

- commercial facilities.

In such places, functionality and quick assembly are the priorities. This solution combines comfort and efficiency, making it a practical choice for facility managers.

Hidden Fixing Panels: Aesthetics and Functionality

Sandwich panels with hidden fixing are the perfect combination of aesthetics and functionality. Their key features are:

- Smooth, uniform surface – no visible connectors thanks to the use of hidden locks.

- Modern and elegant look – ideal for projects where facade aesthetics are a priority.

- High insulating properties – improving the energy efficiency of buildings.

The choice of panels with hidden fastening often results from the need to create a harmonious facade that emphasizes the modern style of the building. Thanks to this, buildings gain not only in appearance, but also in functionality.

Advantages and disadvantages of sandwich panels

Sandwich panels are a versatile building material that is gaining increasing recognition in the industry. Why? First of all, thanks to their numerous advantages. They offer excellent energy efficiency, making them an ideal choice for projects requiring solid thermal insulation. However, like any material, they also have their limitations – their susceptibility to mechanical damage can be a challenge in more difficult conditions.

The decision to use sandwich panels is often based on their ability to reduce heating costs. In the face of rising energy prices, this is an invaluable argument. However, it is worth remembering that intensive use or extreme weather conditions can lead to damage, and their repair is associated with additional costs that must be included in the budget.

Energy efficiency and thermal insulation

One of the greatest advantages of sandwich panels is their energy efficiency. Thanks to their excellent insulation properties, they allow for significant savings in heating costs. They also help maintain a stable temperature inside buildings, which increases the comfort of use and supports environmental protection by reducing energy consumption.

Their thermal insulation is due to the use of modern materials, such as:

- PIR foam – providing excellent thermal insulation,

- mineral wool – effectively reducing heat loss.

This makes sandwich panels perfect for passive and energy-efficient buildings, where every detail related to energy efficiency is important.

Fire resistance and acoustic properties

Mineral wool sandwich panels are distinguished by their fire resistance and excellent acoustic properties. Thanks to the use of non-flammable materials such as mineral wool, they provide additional safety in buildings that must meet strict fire safety standards.

Their acoustic properties make them excellent at muffling sounds, making them an ideal solution for places where peace and quiet are a priority, such as:

- schools,

- hospitals,

- offices.

Acoustic comfort and safety in one? That sounds like a perfect combination!

Cost and durability compared to other materials

The costs of sandwich panels are often very competitive compared to other building materials. This makes them an excellent choice for investors looking for economical solutions. For example:

- polystyrene boards – affordable and easy to install,

- mineral wool boards – more expensive, but offering better insulating and fire protection properties.

Their durability is another significant advantage. Thanks to their resistance to weather conditions and mechanical damage, sandwich panels require less repairs and maintenance, which translates into long-term savings. Compared to traditional materials, they offer a good price-quality ratio – a key factor for investors planning long-term projects.

Assembly and transport of sandwich panels

The assembly and transport of sandwich panels are key stages of every construction, which require precise planning, appropriate tools and proven work methods. Thanks to their modular structure, sandwich panels enable quick and efficient assembly, which significantly shortens the time of project implementation. However, in order for the process to run smoothly, it is necessary to follow the appropriate procedures and use dedicated vehicles for their transport.

Transporting sandwich panels is a challenge due to their delicate structure, which can be easily damaged during transport. Therefore, it is crucial to use specialist vehicles equipped with safety systems that protect the panels from shifting and mechanical damage. Equally important is proper storage of the panels before installation – this allows them to maintain their quality and full functionality.

How to properly install sandwich panels?

Effective assembly of sandwich panels is based on three pillars: precision, experience and the right tools. It is not only about aesthetics, but above all about the durability of the structure, its energy efficiency and resistance to changing weather conditions. Each stage of assembly requires maximum care, because it determines how long the building will fulfill its functions.

- Fit and seal: Precise fit of the panels and their tight sealing helps avoid heat loss and moisture penetration, which affects the comfort of using the building.

- Specialized tools: Jacks, screwdrivers and other tools ensure the stability and safety of the structure.

- Precise attachment: Investing in careful attachment of the panels translates into their durability and reliability for many years.

The most common errors in the assembly of sandwich panels

Although sandwich panels are a modern and easy-to-install material, their incorrect installation can lead to serious problems. One of the most common mistakes is improper fit of the panels, which causes leaks and heat loss. Another problem is the lack of proper sealing of joints, which can result in moisture penetration and the formation of thermal bridges. Another mistake is using the wrong tools, which leads to damage to the surface of the panels. Improper storage of the panels before installation, e.g. on a damp surface, can also negatively affect their insulating properties. To avoid these problems, it is worth following the manufacturer’s recommendations and using the services of experienced specialists. Correct installation guarantees the durability and efficiency of sandwich panels for years.

Tips for transport and storage

Transport and storage of sandwich panels require special attention to maintain their quality and functionality. Here are the key rules:

- Transport: The panels should be transported in vehicles equipped with safety systems that minimize the risk of damage. Solid immobilization of the panels prevents their movement and possible mechanical damage.

- Storage: The boards should be stored on a flat, stable surface, away from moisture and direct sunlight. Such conditions help avoid deformation and loss of insulating properties.

Following the above rules ensures that the sandwich panels will be in perfect condition, ready for installation and fulfilling their role in the building structure.

Sandwich panels in the offer of manufacturers

The construction market offers a wide selection of sandwich panels, which are available from numerous manufacturers. This is great news for investors, because it allows for precise matching of products to the specific requirements of the project. Regardless of whether the priority is technical or aesthetic issues, the choice is truly impressive. However, the decision on the choice of the manufacturer is crucial – it affects the durability and quality of the entire structure. Therefore, it is worth paying attention to the reputation and experience of the supplier, which often determine the success of the investment.

Kingspan – Leader among sandwich panel manufacturers

Kingspan is one of the most recognizable manufacturers of sandwich panels in the world. The brand has gained a reputation thanks to innovative technologies and care for the environment. Kingspan’s key advantage is its unique insulation cores, such as QuadCore® and IPN, which offer exceptional energy efficiency. The company’s sandwich panels are distinguished by excellent thermal and acoustic insulation, as well as fire resistance, which makes them the number one choice in many construction projects. Kingspan also focuses on sustainable development – their products meet rigorous ecological standards and can be used in passive buildings. This is a manufacturer that focuses on quality, innovation and durability, providing solutions tailored to the needs of the most demanding customers.

Why choose sandwich panels?

Sandwich panels are a solution that harmoniously combines modernity, functionality and savings. Their key advantage is energy efficiency. Thanks to their excellent insulation properties, they help maintain a stable temperature inside buildings, which translates into lower heating costs in winter and cooling costs in summer. This makes them irreplaceable in facilities that require meeting rigorous energy standards, such as refrigerated warehouses or passive buildings.

Easy to install and save time

The prefabricated structure of sandwich panels makes their installation quick and simple. This significantly shortens the project implementation time, which translates into lower labor and equipment rental costs. Additionally, their lightweight structure facilitates transport and manipulation on the construction site. This is particularly important for large investments, where every saving of time and effort is significant.

-

Dieta2 lata ago

Dieta2 lata agoTurystyka kulinarna po polskiej regionalnej kuchni

-

Porady2 lata ago

Porady2 lata agoLogistyka w gastronomii – Nowoczesne metody i ich znaczenie

-

Porady2 lata ago

Porady2 lata agoBHP w hotelu – Bezpieczeństwo i higiena pracy

-

Dieta2 lata ago

Dieta2 lata agoCo wiesz o gotowaniu? Quiz kulinarny, sprawdź swój smak!

-

Dieta2 lata ago

Dieta2 lata agoWege catering – zdrowy i smaczny wybór dla Twojej diety

-

Life style2 lata ago

Life style2 lata agoOgródek Restauracyjny – Pomysł na Wyjątkową Przestrzeń

-

Dieta2 lata ago

Dieta2 lata agoCatering dla alergików – Doskonały Wybór dla alergików

-

Life style2 lata ago

Life style2 lata agoMedia społecznościowe – Definicja, korzyści i zastosowania